Drip Strips

With prefabricated KORTE Drip Strips, damage to components, balconies, and the undersides of these is avoided. As a result, the water drips off at the ‚right‘ point.

With prefabricated KORTE Drip Strips, damage to components, balconies, and the undersides of these is avoided. As a result, the water drips off at the ‚right‘ point.

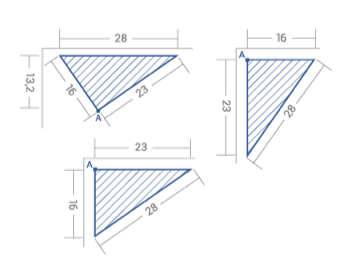

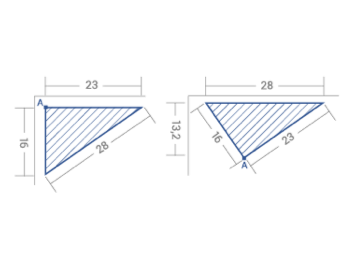

1,000 x 16/23/28 mm (LxWxH)

1,000 x 16/23/28 mm (LxWxH)

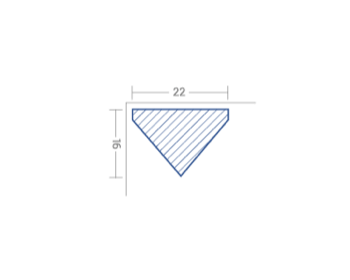

1,000 x 22 x 16 mm (LxWxH)

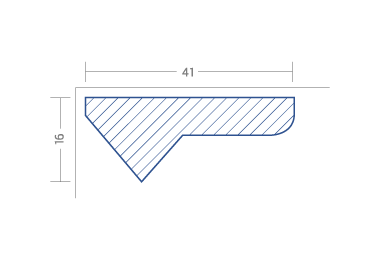

1,000 x 41x 16 mm (LxWxH)

Due to the penetration of moisture and inadequate concrete cover, damage is often caused to the underside of components – rusting steel reinforcement resulting in flaking concrete.

This type of damage can be avoided by using the prefabricated KORTE Drip Strips because water then drips off at the ‚correct‘ point.

Cf.

DIN 18349 Repair work on concrete structures and

DIN 1045 Concrete and reinforced concrete works:

‚Drip Strips are required to protect underside surfaces. The Drip Strips should be located on the transition from the vertical concrete surfaces to the horizontal lower faces.

Forming and restoring drip channels and water drip edges (according to DIN) and repairing damaged edges may require considerable effort due to 1. additional complicated formwork

2. additional supports

3. hindering of other work‘

Issues 1 to 3 are resolved if KORTE Drip Strips are used. See the publication ‚Edge issues‘ by Klaus Korte

To reduce the crack width by 50% in the region of the floor/wall joint, prefabricated KORTE mouldings are a low-cost and time-saving alternative.

Instead of the usual concave elements, KORTE Drip Strip type T3 can be used as the floor/wall joint if this is aesthetically acceptable.

Drip Strip type T3 is inexpensive, quickly and easily installed and has a small gluing or coating surface. Ideal, for example, for multistorey car parks.

Type T3 rigid is used for straight components and type T3 flexible for curved components.

If you want to learn more about our products, please download our information material.

The mouldings are glued over their entire surface with 1-component polyurethane (PU) or 2-component epoxy resin (EP).

The drip strips are smooth and free of pores and can, but do not have to, be coated.

Please consult our handling guidelines for type T2 and type T4 for detailed information.

Please consult our handling guidelines for type T3 rigid and type T3 flexible for detailed information.

Fill out and sign our order form and send it back to us via Fax. We will process your order and inform you.

Private individuals, please note:

We do not supply private individuals. Please contact your chosen plasterer, building company or local builder’s merchant for prices, delivery, etc.