Concave Mouldings

Prefabricated KORTE Concave Mouldings are the ideal solution for details to ensure a clean floor/wall joint.

Prefabricated KORTE Concave Mouldings are the ideal solution for details to ensure a clean floor/wall joint.

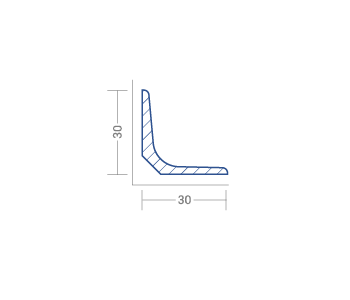

1,000 x 30 x 30 mm (LxWxH)

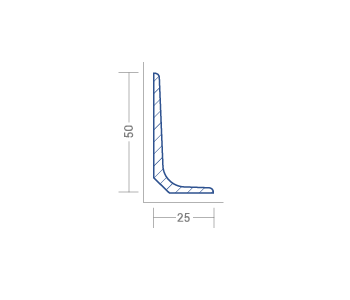

1,000 x 25 x 50 mm (LxWxH)

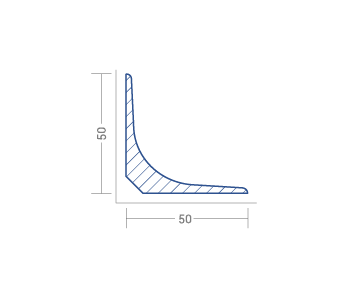

1,000 x 50 x 50 mm (LxWxH)

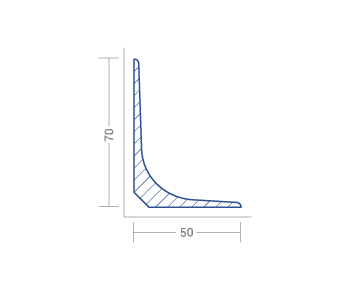

1,000 x 50 x 70 mm (LxWxH)

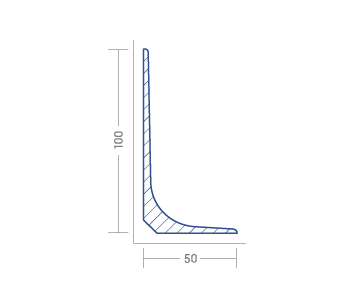

1,000 x 50 x 100 mm (LxWxH)

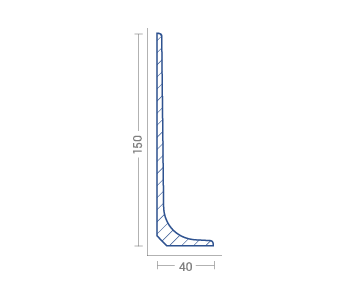

1,000 x 40 x 150 mm (LxWxH)

This type of damage to seals often arises due to inadequate planning and workmanship, unsuitable or deficient materials, but also due to climatic influences (temperature differences, precipitation, heat and frost), and chemical loads (acid rain, CO2 emissions). Moreover, mechanical stress such as abrasion from walking or concentrated loads can cause damage to the coating or covering.

This enables moisture to penetrate the components underneath and results in damage to the building structure.

ndustrially manufactured KORTE Concave Mouldings made of polymer resin are the perfect solution for all floor/wall joints on balconies, terraces, access balconies, etc.

Installation of a Concave Moulding (fillet) without void content between floor and wall is obligatory for hygiene reasons.

For such cases, KORTE Concave Mouldings made of polymer resin provide a fast, clean and aesthetic solution.

Industrially manufactured KORTE Concave Mouldings can be used in hospitals, clean rooms, laboratories, canteen kitchens, industrial halls (food production), wherever cleanness and hygiene are important.

A precast balcony is subsequently fitted. Water runs through the gap between the balcony and the façade onto the balcony below.

This annoys the residents and can dirty the façade.

A KORTE Spitter is fitted on the façade. A KORTE Concave Moulding (e.g. type H100/50) is fitted to the floor of the balcony.

The Spitter now projects beyond the Concave Moulding. This ensures the water runs off at the ‚correct‘ point and prevents damage.

To reduce the crack width by 50% in the region of the floor/wall joint, prefabricated KORTE mouldings are a low-cost and time-saving alternative.

Instead of the usual concave elements, KORTE Drip Strip type T3 can be used as the floor/wall joint if this is aesthetically acceptable.

Drip Strip type T3 is inexpensive, quickly and easily installed and has a small gluing and coating surface. Ideal, for example, for multistorey car parks.

Type T3 rigid is used for straight components and type T3 flexible for curved components.

If you want to learn more about our products, please download our information material.

The mouldings are normally glued with 2-component epoxy resin (EP) to provide a shear-resistant connection and avoid cracking between the floor coating and moulding. The join to the rising wall is effected with 1-component polyurethane (PU), if necessary, with a gap formed according to DIN 18540.

The Concave Mouldings are compatible with most common floor coating systems. Please consult our handling guidelines for detailed information.

PU/EP

Download Flyer „Concave mouldings“

Download handling guidelines „Concave mouldings“

Fill out and sign our order form and send it back to us via Fax. We will process your order and inform you.

Private individuals, please note:

We do not supply private individuals. Please contact your chosen plasterer, building company or local builder’s merchant for prices, delivery, etc.